SPEED PERF6RMANC3

SP63 Stage 2 Built Long Block For Ford Focus RS 2.3L Rated 700hp

- SKU:

- FRS-S2BLB

SP63 Stage 2 Built Long Block For Ford Focus RS 2.3L Rated 700hp

**CONTACT US FOR ETA**

____________________________________________________________________________

Products included in the Stage 2 Long Block package: Rated 700whp

- Mahle 2618 Pistons

- Manley H-Beam Rods (Option for I Beams available)

- SP63 625+ Custom Age Head Studs

- ARP Main Studs

- ACL Tri-Metal Rod Bearings

- ACL Tri-Metal Main Bearings

- Modified crank w/ Teardrop-shaped cavity

- Keyed Crank, Timing Gear & Crank Pulley

- BSD Kit

- Upgraded Valve Springs w/ 7* Lock Conversion

- Stage 3 Cams

- O ring

- Oil baffle included

- Upgraded Heat-treated Intake & Exhaust VVT

- Custom Oil Pump Chain Rail

- Pinned cam gear

- Utilizing 2.0 ST Seasoned Block (Exhaust Manifold Spacer is needed for Stock & NX2 Turbos)

- 3yr warranty!

Here are the brand-new stock replacement items included in the price:

- Timing Chain

- Timing Chain Guides

- Oil Pickup

- Oil Pump

- All Gaskets replaced: See here

*Price also includes Injector Service!* - See here

*When selecting “New Block” you will be getting a new long block utilizing a 2.0TS bottom end, that is then stroked to a 2.3L*

____________________________________________________________________________

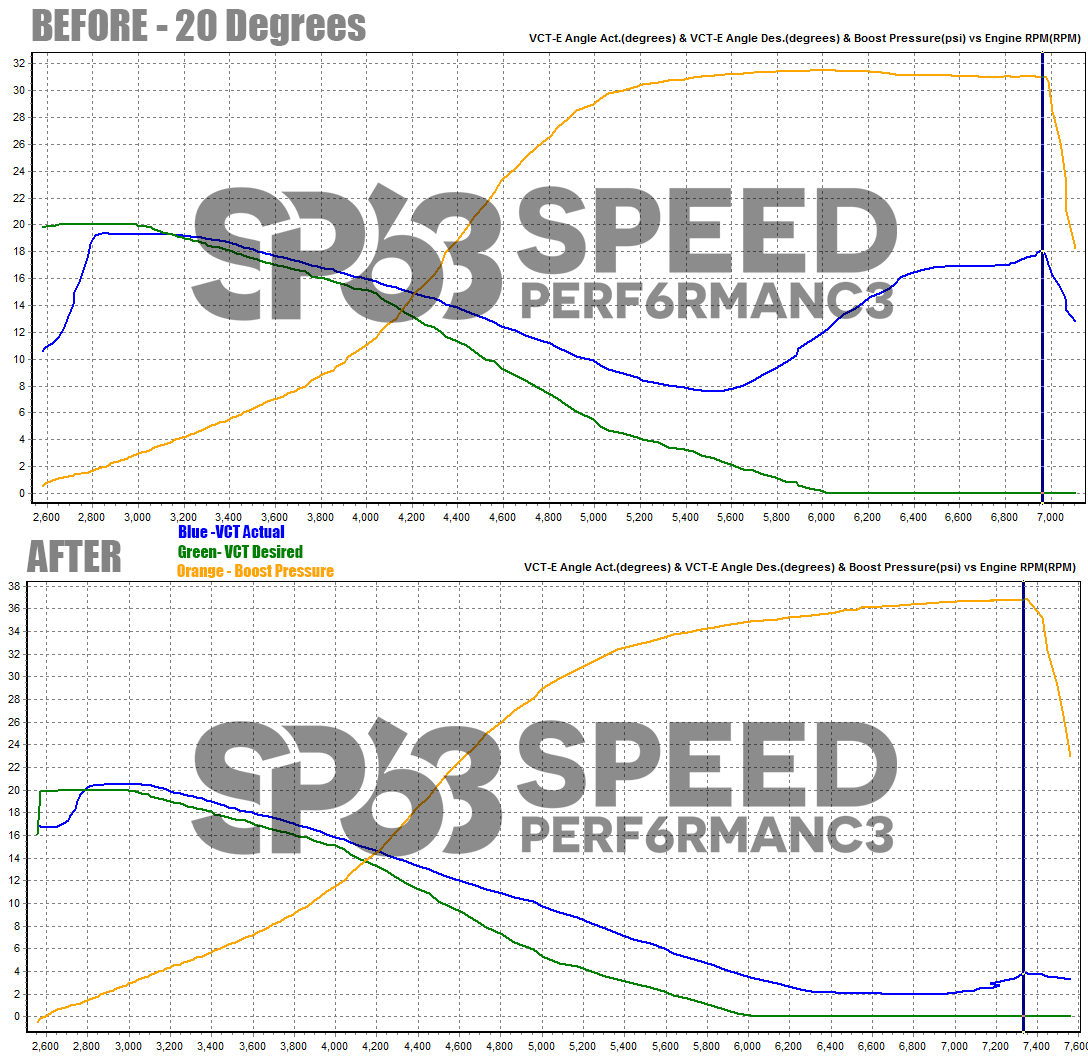

NO VVT RUNAWAY!

Machining Process

Your used engine will go through the entire machine shop process to ensure it meets the highest specifications and tolerances. We first put the engine through our tear down process to properly inspect and clean all engine parts in our hot tank. Then the engine is inspected using a magnaflux system in-house. If any failure is to be found, you will be contacted. The block is then bored and plate honed using a torque plate. Final clearances are checked and the block goes through a final cleaning to make sure there are no debris left over from the machining process.

____________________________________________________________________________

Assembling Process

The cylinder head is then fully inspected separately by pressure testing and magnafluxing to ensure there are no cracks. Valves, Valve Guides and Valve Seats are also examined for excessive wear. In addition, the Cylinder head is carefully checked for warpage. This includes the block deck, intake deck & exhaust deck. After passing the examination process, the Cylinder head is milled and then reassembled while lapping the Intake & Exhaust valves for proper seating. We install Viton Valve Seals for maximum oil control and seal durability throughout the entire rpm range.

After the head is fully assembled, we then proceed with setting the Lash for the Valves. This is a crucial element in the process as it's what ensures that the valves in the head open and close accordingly with the correct clearance.

Piston to wall clearances are re-checked to reduce the amount of contact area against the cylinder wall when the piston "rocks over" during the transition from T.D.C (Top Dead Center). The Long Block is reassembled then it goes through our heat-cycling process. This will bring the engine itself up to Operating Temps (200*F) to re-torque the cylinder head studs once they endure a heat cycle.

____________________________________________________________________________

Shipping

All long blocks have a fixed shipping price of $700, short blocks is $450. Price is to the contiguous USA only.

____________________________________________________________________________

Core Charge

Details on the core charge can be found HERE

____________________________________________________________________________

Warranty

Every SP63 engine now comes with a 12 month, 12,000 mile limited warranty. More details can be found on our warranty page HERE

____________________________________________________________________________

*Important Notes*

NEW engines do NOT come with a valve cover OR oil control valves.

Nam tempus turpis at metus scelerisque placerat nulla deumantos solicitud felis. Pellentesque diam dolor, elementum etos lobortis des mollis ut risus. Sedcus faucibus an sullamcorper mattis drostique des commodo pharetras loremos.

Returns Policy

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

Maecenas placerat ipsum vitae elementum vulputate. Morbi lacinia libero lorem, in dignissim ante convallis at. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Sed in purus vulputate sem tempor tincidunt ac sed turpis

Neque porro quisquam est qui dolorem ipsum quia dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nulla at venenatis eros. Nulla efficitur, orci ut cursus consectetur, nisi elit convallis odio, non hendrerit arcu tortor aliquet eros. Nullam imperdiet diam ut neque ullamcorper semper. Mauris consequat ex sed elit venenatis, eu varius nulla posuere. Nullam gravida mattis velit, id commodo nunc rhoncus ut. Phasellus congue felis tortor, nec eleifend lacus tincidunt vitae. Nullam dapibus tempus tempor. Maecenas massa neque, tempus in efficitur at, scelerisque sed tortor. Morbi vulputate ipsum odio, non posuere sem suscipit accumsan. Cras fermentum nunc quis tempor iaculis. Praesent dictum augue sit amet neque faucibus, ac varius enim convallis. Curabitur volutpat ligula sit amet nibh vehicula egestas. Etiam eget dolor ipsum. Phasellus varius, metus sit amet aliquet tempor, erat ante rhoncus magna, quis vehicula tortor nunc at ipsum. Duis vitae erat vitae turpis cursus pretium. Quisque pulvinar sapien at mi efficitur, sed faucibus nulla accumsan.

Ut a leo interdum, imperdiet ante quis, euismod quam. Nam eget auctor risus. In a bibendum diam. Curabitur non lectus pharetra, maximus dolor mattis, auctor dolor. Maecenas placerat ipsum vitae elementum vulputate. Morbi lacinia libero lorem, in dignissim ante convallis at. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Sed in purus vulputate sem tempor tincidunt ac sed turpis. Pellentesque erat justo, feugiat eget vestibulum molestie, cursus ac ex. Phasellus magna enim, placerat non lacus varius, cursus consectetur urna

Phasellus finibus nulla vitae malesuada efficitur. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Phasellus sed pharetra risus. Quisque ante sem, faucibus id velit eget, bibendum sodales purus. Donec congue ipsum leo, aliquet aliquam lectus suscipit et. Pellentesque viverra, enim et pulvinar aliquet, dolor magna gravida lectus, sit amet pellentesque turpis elit id enim. Nulla a lectus viverra, ultricies urna ac, cursus turpis. Sed et purus vitae nunc molestie molestie sit amet eget nisl. Ut non nunc erat. Orci varius natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Orci varius natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus

Suspendisse imperdiet enim in porttitor dignissim. Nam iaculis enim vel nunc commodo cursus. Donec vitae magna eget nunc fringilla pharetra vitae id risus. Proin in aliquam ex. Ut purus sem, fermentum ut aliquam at, ornare quis nisl. Aliquam feugiat dapibus nunc, sit amet aliquam metus sollicitudin eget. Integer gravida ligula vitae leo suscipit, eget pretium augue tempus. Integer fringilla justo id purus pulvinar iaculis. Fusce in lorem pulvinar, suscipit ipsum id, volutpat dui. Fusce eu sem sapien. Duis sit amet nisi leo.

Nam tempus turpis at metus scelerisque placerat nulla deumantos solicitud felis. Pellentesque diam dolor, elementum etos lobortis des mollis ut risus. Sedcus faucibus an sullamcorper mattis drostique des commodo pharetras loremos.

-

Nam tempus turpis an metus loremous nulla deumantos?

Nam tempus turpis at metus scelerisque placerat nulla deumantos solicitud felis. Pellentesque diam dolor, elementum etos lobortis des mollis ut risus. Sedcus faucibus an sullamcorper mattis drostique des commodo pharetras loremos. Donec pretium egestas sapien an mollis. Suspendisse vestibulum lectus in lectus volutpat danos dapibus purus pulvinar.

-

Dinterdum pretium de dan mauris condimentus?

Etiam id faucibus enim, eget mattis augue. Sed a felis eget tellus cursus commodo. Vivamus elementum elit quis neque feugiat molestie ut condimentum metus. Duis tempus tortor mollis, congue diam et, ornare sapien. Ut sed interdum sem. Vivamus facilisis, libero in suscipit scelerisque, lectus dolor faucibus justo, nec porta est libero quis nibh. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Donec vel aliquam elit, et sagittis diam.

-

Pellentesque diam dolor de melementum etos lobortis?

Donec consequat laoreet vulputate. Integer non ligula lacus. Praesent malesuada urna in eros rutrum congue. Proin iaculis, neque nec consectetur bibendum, ex mi tristique ex, non aliquet erat nunc faucibus nunc. Mauris nec nisl at magna vehicula molestie. Aenean mattis, nisl vel ornare sodales, felis est volutpat justo

-

Placerat nulla deumantos solicitud felis?

Sed rutrum condimentum sem sit amet dictum. Mauris sed congue tortor, eu malesuada nunc. Suspendisse dapibus in nibh sit amet molestie. Mauris ultrices dolor ut sapien aliquam dictum. Cras bibendum, urna sit amet dignissim elementum, libero nisi condimentum ex, sed hendrerit lacus augue in risus. Proin id fringilla nulla. Suspendisse vitae tempor ipsum. Phasellus tempor consequat est, sit amet rutrum lorem commodo sit amet. Suspendisse id orci non risus sodales fermentum vitae quis lacus

-

Mauris non sem tincidunt hendreritos?

Nullam nec finibus magna. Nulla rhoncus, nunc ut sollicitudin euismod, mauris diam interdum ipsum, ut semper ante magna non augue. Aliquam lectus augue, venenatis eget luctus nec, finibus in turpis. Phasellus at enim augue. Sed rutrum non diam sollicitudin sagittis. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

-

Duis an pharetra justo aliquam quis fermentum leo tincidunt felis?

Quisque cursus accumsan aliquam. Phasellus et luctus dolor, quis imperdiet dui. Curabitur in ligula quis dui iaculis elementum luctus a diam. Vivamus dolor mauris, dignissim ut porta vitae, laoreet at nunc. Integer consequat ornare sapien, a tincidunt leo

-

Morbi pretium nibh vitae nisl semper dullamcorper?

Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Donec ornare eget urna a tincidunt.

Phasellus at enim augue. Sed rutrum non diam sollicitudin sagittis. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Quisque cursus accumsan aliquam. Phasellus et luctus dolor, quis imperdiet dui. Curabitur in ligula quis dui iaculis elementum luctus a diam. Vivamus dolor mauris, dignissim ut porta vitae, laoreet at nunc. Integer consequat ornare sapien, a tincidunt leo -

Cras multricies nulla porttitor metus cursus malesuada?

Proin id fringilla nulla. Suspendisse vitae tempor ipsum. Phasellus tempor consequat est, sit amet rutrum lorem commodo sit amet. Suspendisse id orci non risus sodales fermentum vitae quis lacus. Cras lobortis posuere purus, a ullamcorper diam sollicitudin vitae. Etiam elementum suscipit tristique. Phasellus eleifend sagittis magna et condimentum.

-

Lorem ipsum dolor sit amet consectetur adipiscing elit mecenas deget sagittis?

Mauris nec nisl at magna vehicula molestie. Aenean mattis, nisl vel ornare sodales, felis est volutpat justo, a ornare lacus urna non nibh. Suspendisse tempor velit sit amet dui finibus malesuada. Pellentesque vitae nulla eu mi elementum porttitor in non magna. Quisque ut volutpat augue, et faucibus dui. Quisque sit amet diam dui. Phasellus eu finibus sapien, id lacinia ante. Mauris et suscipit ex, a pellentesque mi. Maecenas sem urna, porta at scelerisque et, euismod sed dui. Aliquam imperdiet velit justo, at feugiat purus elementum in